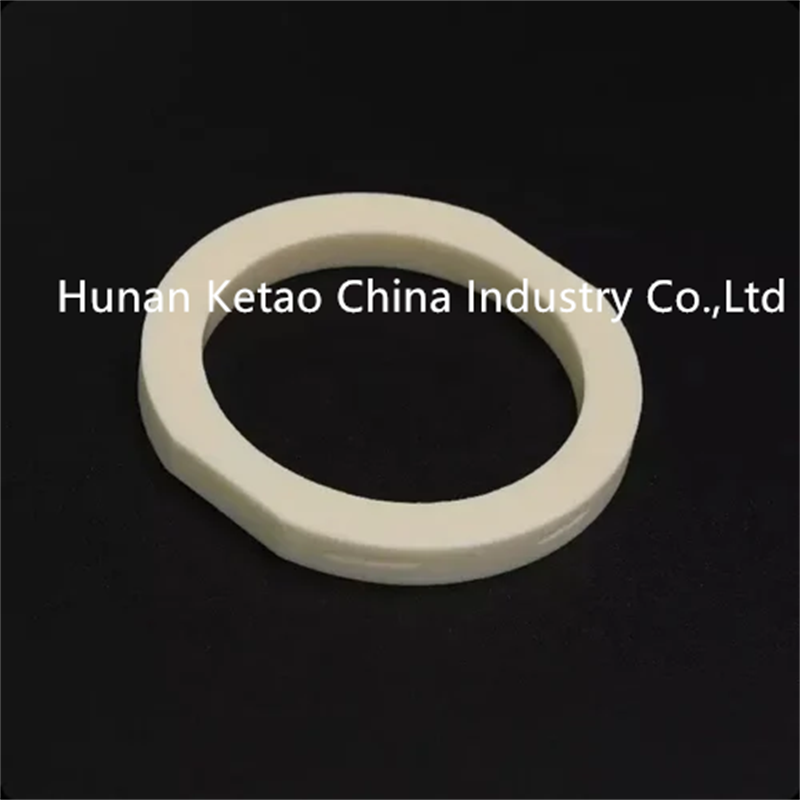

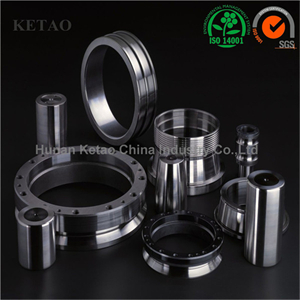

Alumina ceramic ring is a cylindrical or toroidal-shaped component made of alumina ceramic material. It is used in various applications where high wear resistance, high temperature stability, and chemical resistance are required. The ring can be either solid or hollow, depending on the intended use and application. Some common uses of alumina ceramic rings include bearings, mechanical seals, pump components, and industrial furnace components. Alumina ceramic rings are also used in the jewelry industry as a material for making high-end rings due to its hardness and scratch resistance.