-

Excellent Wear Resistance: RBSiC exhibits exceptional wear resistance, making it suitable for applications where components are subjected to abrasive and erosive wear. It can withstand high-velocity particle impact and sliding abrasion.

-

High Strength and Toughness: RBSiC has a high flexural strength and toughness, enabling it to withstand mechanical stresses and resist fracture or deformation. It can handle high loads and impacts, making it ideal for demanding applications.

-

Corrosion and Chemical Resistance: RBSiC has excellent resistance to corrosive environments and chemical attack. It can withstand harsh acids, alkalis, and other aggressive chemicals, making it suitable for chemical processing applications.

-

Thermal Shock Resistance: RBSiC has good thermal shock resistance, allowing it to withstand rapid temperature changes without cracking or failure. This property makes it suitable for applications involving thermal cycling.

-

High Temperature Capability: RBSiC can withstand high temperatures, making it suitable for applications in elevated temperature environments. It retains its mechanical properties at high temperatures, ensuring reliable performance.

-

Electrical Insulation: RBSiC exhibits good electrical insulation properties, making it suitable for electrical and electronic applications that require both thermal and electrical insulation.

-

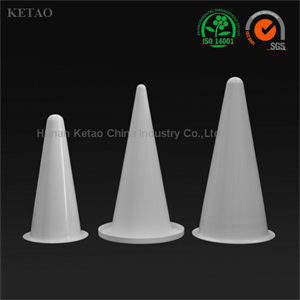

Pump and Valve Components: RBSiC is commonly used in pump and valve components, such as impellers, bearings, and sealing rings. Its wear resistance and corrosion resistance make it suitable for applications in the chemical, oil and gas, and water treatment industries.

-

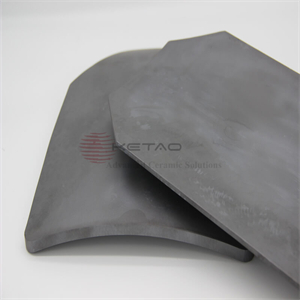

Mechanical Seals: RBSiC is utilized in mechanical seal faces due to its exceptional wear resistance and ability to withstand abrasive media. It ensures reliable sealing and extended service life in various industrial applications.

-

Kiln Furniture and Refractories: RBSiC is used in kiln furniture, including shelves, supports, and setters, due to its high-temperature capability, thermal shock resistance, and dimensional stability. It finds application in the ceramics, glass, and heat treatment industries.

-

Semiconductor and Electronics: RBSiC is employed in the semiconductor and electronics industry for applications such as wafer carriers, heating elements, and susceptors. Its high-temperature stability and electrical insulation properties are advantageous in these applications.

-

Aerospace and Defense: RBSiC finds application in the aerospace and defense sectors for components that require high strength, wear resistance, and thermal stability. Examples include nozzles, armor, and aircraft engine components.

-

Mining and Minerals Processing: RBSiC is used in mining and minerals processing equipment, such as cyclone liners, slurry pump parts, and hydrocyclones, due to its excellent wear resistance and ability to handle abrasive slurries.